Downloads

- Shell: aluminum, stainless steel

- Shell plating:

- Aluminum shell: Nickel (F)

- Olive drab cadmium (W) Black zinc nickel (Z)

- Stainless steel shell: Passivated (K)

- Insulator: Thermoplastic or thermoset

- Grommet and interfacial seal: Silicone elastomer

- Endurance: 500 mating/unmating operations

- Sealing: 10-6 atm.cm3/s unmated (helium gas test)

- Temperature range: -65°C +175°C

- Salt spray resistance : Black Zinc Nickel (aluminum shell) available for RoHS high corrosion resistance (500 Hrs)

- Standards & specifications according to MIL-DTL-38999 Series 3 (EN3645-003)

Key features and benefits

Description

The 8DB series is a feedthrough connector with double ended receptacles mounted on a panel allowing cable plug connections on both sides of the bulkhead. 8DB connectors meet the 38999 series III performance and provide standard 38999 series III mating interfaces and layouts (contacts from #22 to #8 signal and power).

8DB connectors decrease electrical installation workload during design and final assembly compared to conventional non-repairable potted feedthroughs: no more compounds!

The standard reinforced sealing technology used in 8DB connectors allows leak rates lower than 10-6 atm.cm3/s under ∆P=1 bar

Alternatives to stainless steel male-male glass fused feedthroughs are available:

- Weight saving : aluminum shells more than 2 times lighter than stainless steel equivalent

- No mirror female plugs needed.

New: a QPL Black Zinc Nickel on aluminum is available for better corrosion resistance.

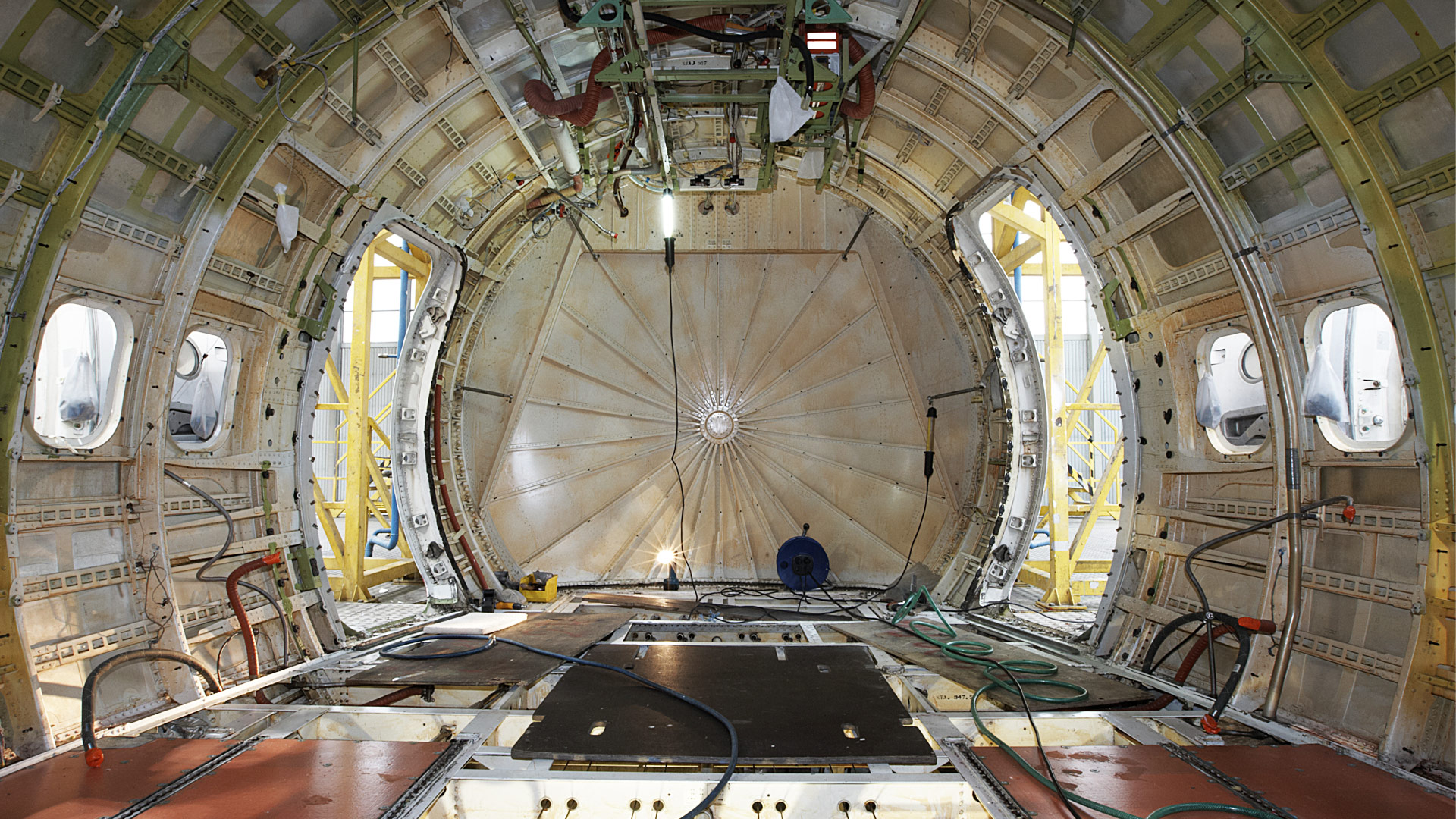

Examples of application field

8DB connectors are suited to withstand harsh environmental conditions for aviation applications.